- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

Ceramic powder is a key basic material for the development of modern industry and technology. The main components of ceramic powders include clay, quartz, and feldspar for traditional ceramics, as well as alumina, zirconia, silicon nitride, and silicon carbide for advanced ceramics. From dishes in daily life to rocket engine components in the high-tech field, ceramic powders with different properties are indispensable. With the development of new technologies such as nanotechnology and 3D printing, the preparation and application of ceramic powders are constantly expanding new boundaries.

Testing the particle size distribution of ceramic powders is a crucial step in the preparation of ceramic materials, as it directly and profoundly affects the performance, quality and production process of ceramic products.

1. Determines sintering activity and density: Finer powders have a greater specific surface area and a stronger sintering driving force, helping to produce denser, stronger ceramics at lower temperatures. A reasonable particle size distribution (a mix of coarse and fine particles) can increase the powder's bulk density and reduce sintering shrinkage and porosity.

2. Impact on the performance of the final product: Particle size directly determines the microstructure of the ceramic after sintering (such as grain size), which in turn affects its key properties such as mechanical strength, hardness, wear resistance, electrical insulation and thermal conductivity.

3. Control production process stability: Consistent particle size distribution is a prerequisite for ensuring batch production stability. It affects the flowability and formability of powders (such as dry pressing and injection molding) and the rheological properties of slurries (such as tape casting), ensuring uniform green body quality and reducing defects.

Laser particle size analyzers are a core quality control tool in the ceramics industry. By quickly and accurately measuring the particle size distribution of raw powders, they optimize slurry properties and molding processes, and predict sintering activity. This effectively controls the density, strength, and microstructural consistency of the final product, crucial for improving product performance and production efficiency.

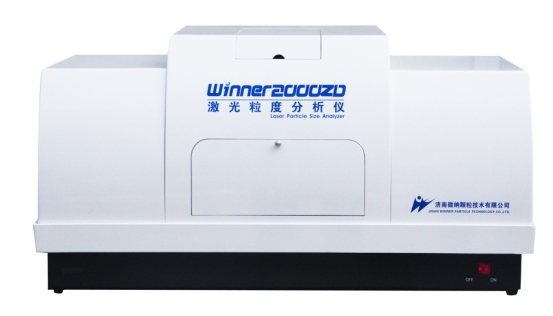

This time, Winner2000ZDE is recommended to test the particle size distribution of ceramic powders. Winner2000ZDE intelligent wet laser particle size analyzer utilizes a scattered light detection system and is equipped with a highly sensitive ring-type photoelectric detector. It features automatic optical path alignment and one-touch testing. This not only increases testing speed but also eliminates human interference, ensuring accurate test results.

The test range is 0.1-300μm. It is mainly used to test the particle size of water-insoluble solid powders or particle samples in emulsions.

Measuring instrument information is as follows:

The video of measuring particles is as follows:

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer