- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

Ore pulp is the "blood" of the modern mineral processing industry. Most mineral processing operations are completed in a ore pulp state. It is the core medium for mineral processing and is mainly composed of finely ground solid mineral particles, water, and flotation reagents. By adjusting the ore pulp concentration, fineness and reagent system, useful minerals and gangue can be efficiently separated, which is the basis of mineral processing and hydrometallurgy.

The core purpose of testing the particle size distribution of ore pulp is to optimize sorting efficiency and control production costs.

1. Determines the degree of mineral dissociation: Particle size directly affects whether useful minerals and gangue are fully "dissociated". If the particle size is too coarse, the useful minerals are not fully dissociated and will be lost in the tailings, reducing recovery rates. If the particle size is too fine, mudding occurs, making separation difficult and affecting concentrate grade.

2. Influences sorting performance: Proper particle size distribution is a prerequisite for achieving ideal recovery rates and concentrate grades in flotation and gravity separation processes.

3. Optimize reagent and energy consumption: Appropriate particle size can significantly reduce flotation reagent consumption and avoid the huge energy waste caused by excessive grinding.

In short, particle size distribution is the core technical indicator for controlling mineral processing efficiency and reducing costs.

The application of laser particle size analyzer in oreore pulp transforms particle size detection from an offline, lagging laboratory analysis method to an online, real-time process control tool. It is like the "eyes" of the grinding and grading system, allowing operators to "see" the changes in particles and make precise and rapid adjustments accordingly, ultimately achieving the comprehensive goals of stabilizing particle size, improving recovery rate, reducing energy and chemical consumption, and improving product quality. It is an indispensable core equipment in modern intelligent mineral processing plants.

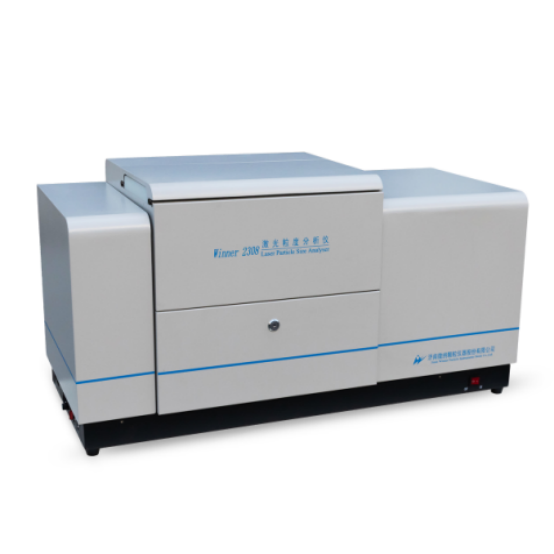

This time, Winner2308A is recommended to test the particle size distribution of ore pulp. Winner2308A wet and dry integrated laser particle size analyzer can switch between dry and wet dispersion with one click. Various technical difficulties of the wet and dry integrated machine have been solved. It is well received by institutions and universities. Its testing range is 0.01-2000μm (wet) and 0.1-2000μm (dry). It features a dual-optical design with a wide testing range and fully automatic intelligent operation.

Measuring instrument information is as follows:

The video of measuring particles is as follows:

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer