- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

Manufactured sand refers to sand particles artificially processed by mechanical equipment (mainly sand making machines). It has significant advantages such as wide sources, controllable quality, and stable performance, and has become an indispensable basic material in modern engineering construction.

The particle size distribution and morphology of manufactured sand are the core parameters that determine the performance of concrete. Traditional screening methods can only provide a rough range of particle sizes and cannot quantify key morphological indicators. The application of particle image analyzers has brought revolutionary breakthroughs in the quality control of machine-made sand:

1. Engineering significance of particle size and morphology

Accurately mastering the particle size and morphology data is the basis for scientifically designing the concrete/mortar mix ratio. Based on this, the water demand can be more accurately predicted, the appropriate admixture dosage can be selected, and quality accidents or material waste (such as excessive use of cement or admixtures) caused by fluctuations in sand properties can be avoided.

2. Breakthrough Application of Image Analyzer

Accurate quantification of morphology: Automatically measure particle size, aspect ratio, sphericity, and other particle morphology parameters. Accurately identify particle content and distribution, and can process tens of thousands of particles per minute (200 times that of a manual microscope), fully ensuring the representativeness of the sample and improving accuracy and repeatability.

Dynamic gradation analysis: Reflects the gradation characteristics more carefully, especially for machine-made sand dominated by non-spherical particles. The results can better reflect the true geometric characteristics of the particles than the screening method based on volume or weight. Detects the distribution of ultra-fine particles of 0.075-5mm (the screening method has an error of 30%).

3. Quality Control Benefits

The content of Class I sand needles and flakes is stably controlled within 5% as required by GB/T 14684.

The deviation of concrete water requirement is predicted to be <3%, which reduces the waste of trial mixing.

Provide morphology access certification for high-strength pumping concrete (above C60).

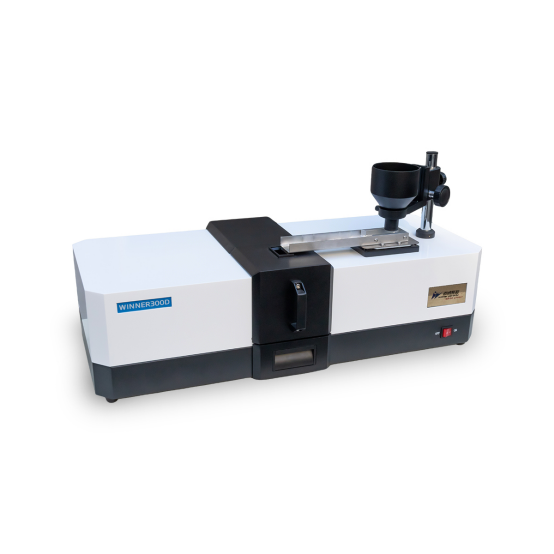

Conclusion: This technology not only solves the blind spots of traditional detection through the simultaneous analysis of particle size and morphology, but also provides a data foundation for high-performance concrete. This time, Winner 300D is recommended to test the particle size distribution and morphology of manufactured sand for customers.

Measuring instrument information is as follows:

The video of measuring particles is as follows:

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer