- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

As one of the most abundant minerals in nature, calcium carbonate has the characteristics of low cost and stable performance. The particle size distribution is related to the core function, production cost and terminal quality of calcium carbonate.

1. Functional control

Filling/reinforcement efficiency: In plastics and rubber, fine particles (such as micron-sized particles) improve strength and gloss; coarse particles lead to reduced performance.

Hiding power (papermaking/paint): Particles with a particle size of ≤2μm significantly improve hiding rate and whiteness.

2. Process adaptability

Dispersion stability: wide distribution is easy to agglomerate and settle, while narrow distribution ensures uniformity.

Processing fluidity: reasonable particle size avoids clogging of equipment and optimizes production efficiency.

3. Quality consistency

Monitor batch fluctuations to ensure stable performance of downstream products (such as high-end plastic films).

Pharmaceutical/food grade must meet particle size standards to ensure bioavailability.

Therefore, it is very important to test the particle size distribution of calcium carbonate, which is one of the functions of the laser particle size analyzer. With its fast, accurate and fully automatic characteristics, the laser particle size analyzer has become a key equipment for improving the quality and efficiency of the calcium carbonate industry.

1. Production process control

Raw material screening: Rapidly analyze the particle size of the ore after crushing to ensure that the raw materials meet the processing requirements (such as the D50 value range).

Grinding optimization: Real-time monitoring of grinding fineness (such as the target below 2μm) to avoid over-grinding or under-grinding and reduce energy consumption.

2. Product quality assurance

Grading accuracy: verify the grading process effect (such as distinguishing 800 mesh/1250 mesh products) to ensure that D97 meets the standard.

Batch consistency: each batch is sampled to prevent particle size fluctuations from affecting downstream applications (such as plastic strength and paper coating uniformity).

3. Application performance correlation

Plastic/rubber: fine particles (D50=1~3μm) improve mechanical properties;

Paper coating: narrow distribution particles (D90≤2μm) ensure hiding power;

Desulfurizer: coarse particles (D50>20μm) control reaction rate.

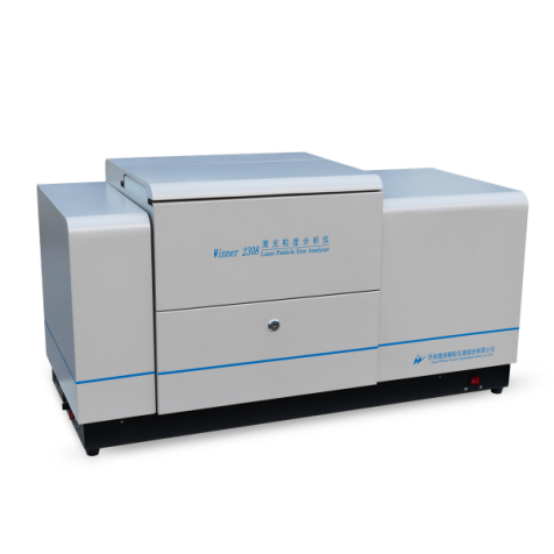

This time, Winner 2308A is recommended to test the particle size distribution of calcium carbonate powder for customers.

Measuring instrument information is as follows:

The video of measuring particles is as follows:

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer