- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

Lithium carbonate has become a strategic resource for promoting sustainable energy revolution and the development of modern society due to its excellent electrochemical properties and mature industrial foundation.

1. Lithium battery core raw materials: As the key raw material for lithium-ion battery positive electrode materials, it provides power for new energy vehicles, electronic products and energy storage systems. It is also the cornerstone of energy transformation.

2. Medical field: As a mood stabilizer, it is used to treat bipolar disorder and regulate nervous system function.

3. Industrial application: used in special glass, ceramic glaze (to reduce melting point and improve thermal stability), and to improve current efficiency and reduce energy consumption in aluminum smelting.

Particle size distribution is the "invisible ruler" that connects the entire chain of lithium carbonate from production to application. Laser particle size analyzers run through the entire process of lithium carbonate production, quality inspection and research and development.

1. Closed-loop control of production process

Crystallization process monitoring: Dynamically optimize crystallization temperature, stirring rate and additive concentration to avoid excessive agglomeration or crushing.

Drying and crushing: Detect the particle size distribution of the dried powder. Guide the crusher parameters (such as speed, time) to ensure that the finished product meets the target range (such as D50=5–15μm).

2. Product quality classification

Battery grade/industrial grade classification: Rapid classification through key indicators such as D10, D50, D90 (e.g. battery grade requires D90≤20μm). Screen out coarse particle impurities to meet the uniformity requirements of downstream positive electrode material sintering.

Medicinal grade fine control: Ensure that 95% of particles are in the range of 1–10μm to ensure drug dissolution rate and bioavailability.

3. R&D material optimization

Morphology-performance correlation study: Correlate particle size distribution with battery rate performance, cycle life and other data to guide the design of high energy density materials.

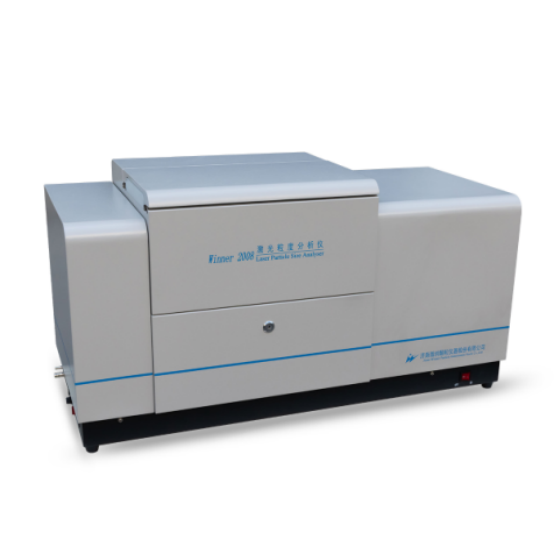

Therefore, laser particle size analyzer plays an irreplaceable role in ensuring the performance of lithium battery materials due to its high efficiency, accuracy and non-contact characteristics. This time, Winner 2008 is recommended to test the particle size distribution of silica powder for customers.

Measuring instrument information is as follows:

The video of measuring particles is as follows:

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer